Social responsibility has always been at the heart of our company’s philosophy, guiding our daily actions. We view sustainability as a continuous journey, woven into everything we do. This commitment is evident not only in our products but also in how we care for our employees and develop our value chains.

We handle raw materials and resources with care. All our trims are OEKO TEX certified from interlinings to zips. All poly bags used as packaging material are 100% recyclable made of 50 microns and above. Our hanger and poly bags suppliers are GRS certified. We are proud partners of brands and mills that are BCI certified, and have switched to LIVAECO yarns which is made from a natural fiber and is pro planet.

Our manufacturing process adheres to strict environmental standards to minimize our carbon footprint. We also implement water-saving technologies to reduce our overall consumption. By prioritizing sustainable practices, we aim to lead the industry towards a greener future.

We guarantee high SOCIAL & ETHICAL standards and working conditions for which we ourselves take responsibility.

We are a Sedex compliant factory. The goal is to exceed requirement of local legislation and reach global standard thereby supporting brands and their sourcing principle.

ASPS supports its workers by setting up welfare committees, adequate canteen space, safe drinking water, to ensure that workers are comfortable at workplace.

Our workplace safety measures include clearly marked emergency routes and exits and thoughtfully planned layouts. All instructions and working signs are posted in visible places and in local languages as per ISO standards.

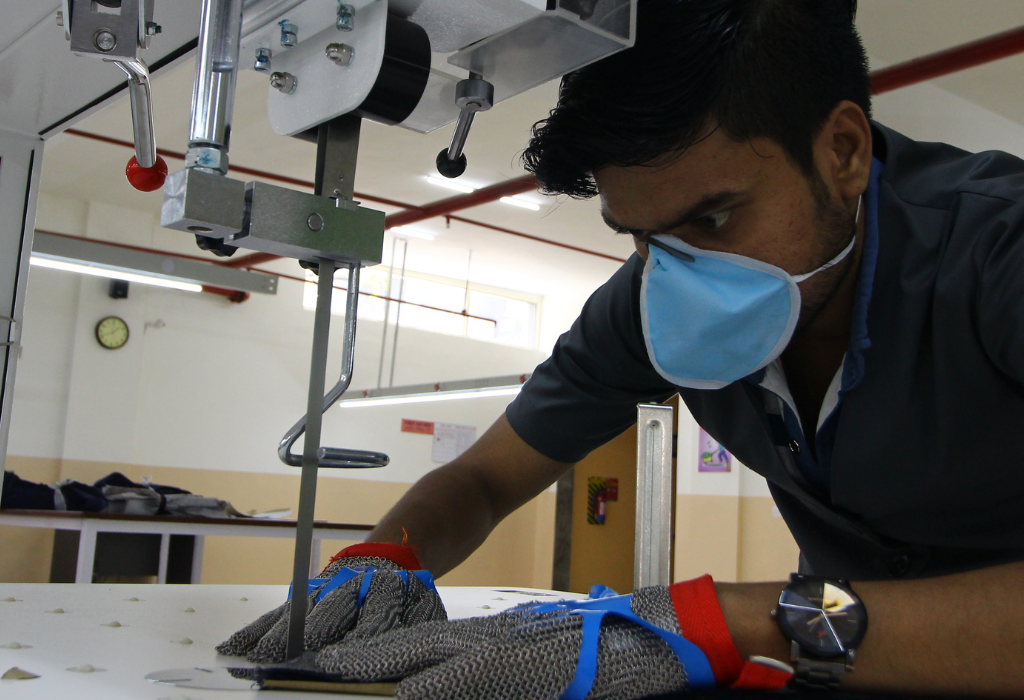

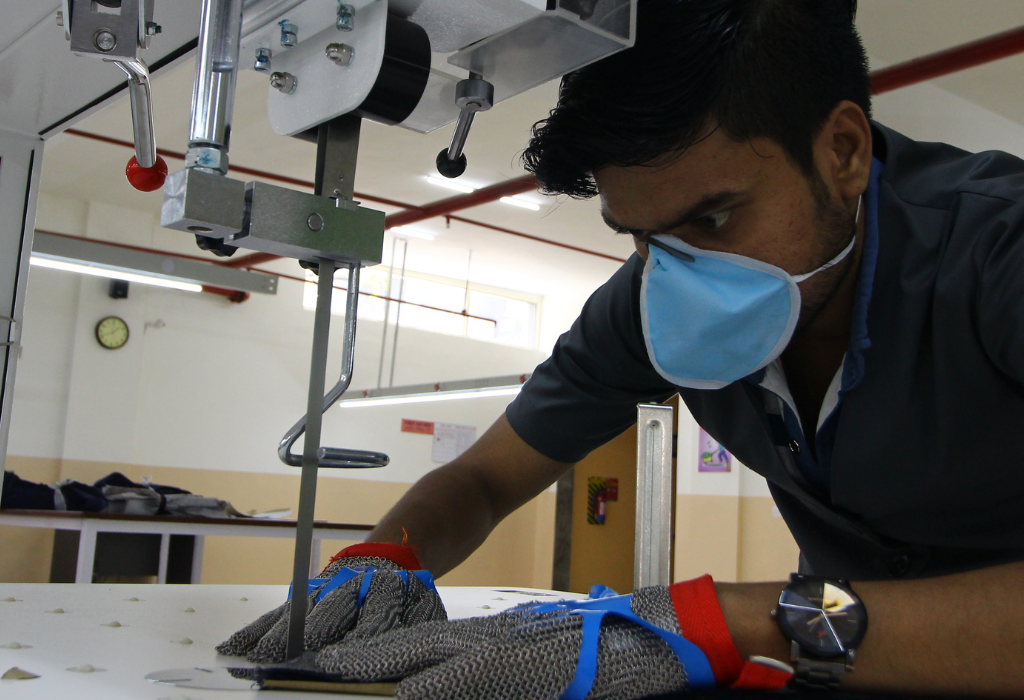

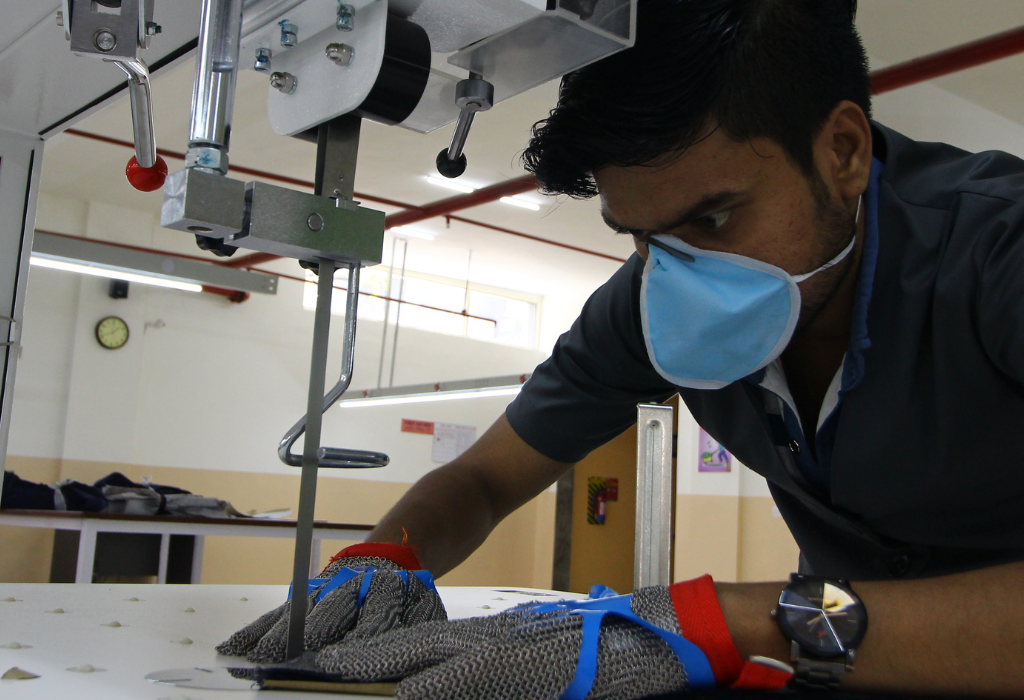

For the safety of our workers we have enforced the use of safety equipments like metal gloves while cutting, needle guards during sewing. Such procedures reduce work related accidents significantly.

ASPS is a 100% fire compliant factory and has fire NOC from fire authorities.

125 smoke detectors across the factory.

85 fire extinguishers.

Monthly training of all employees.

Illuminated fire exits.

Automatic fire extinguishing pumps.

Full internal water pipeline in basement.

Sensor driven fire extinguisher at high risk area.

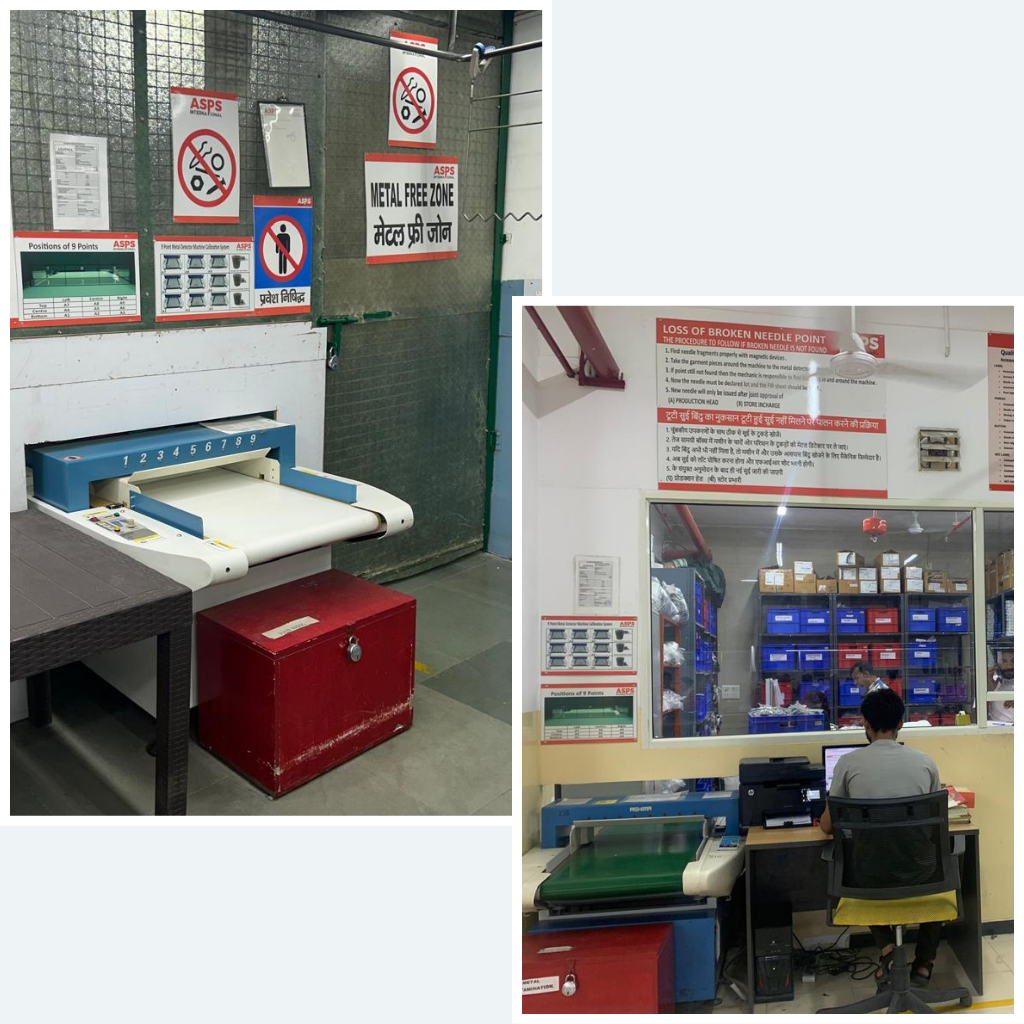

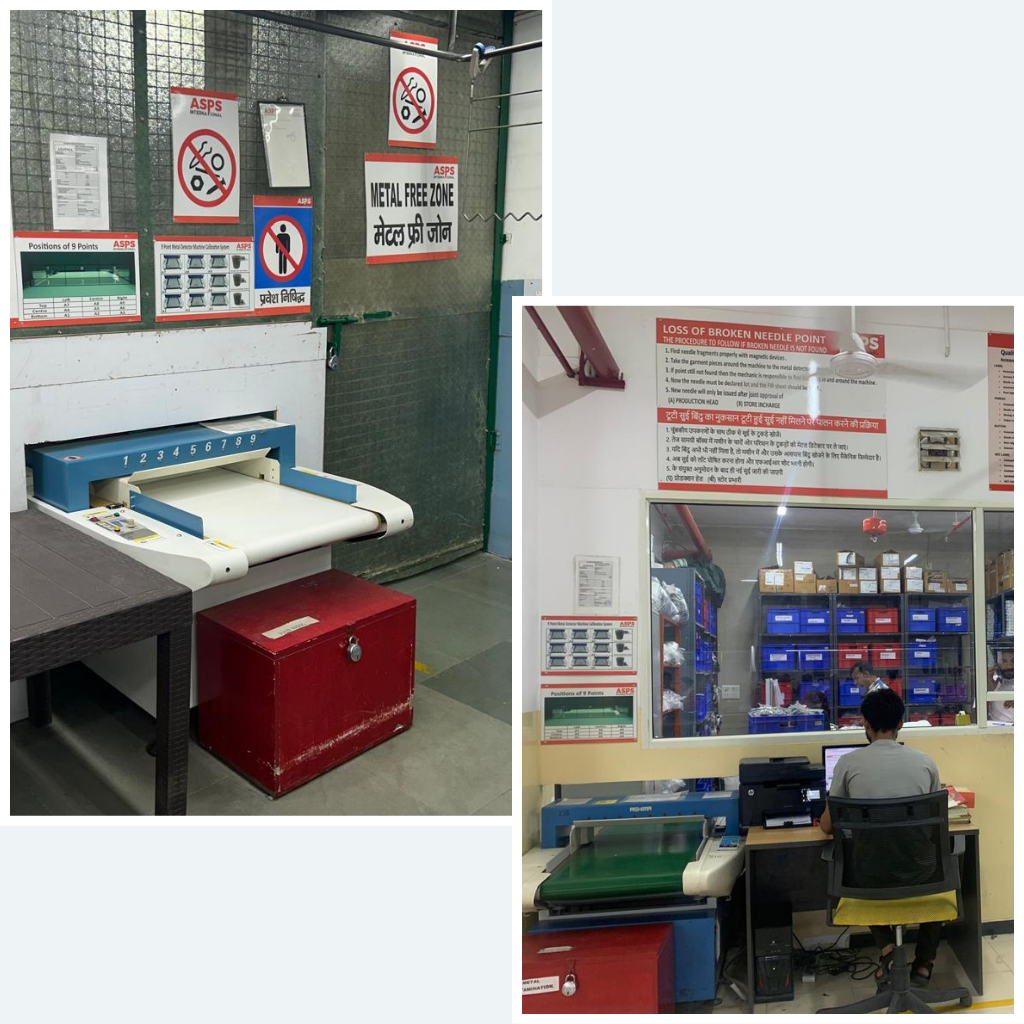

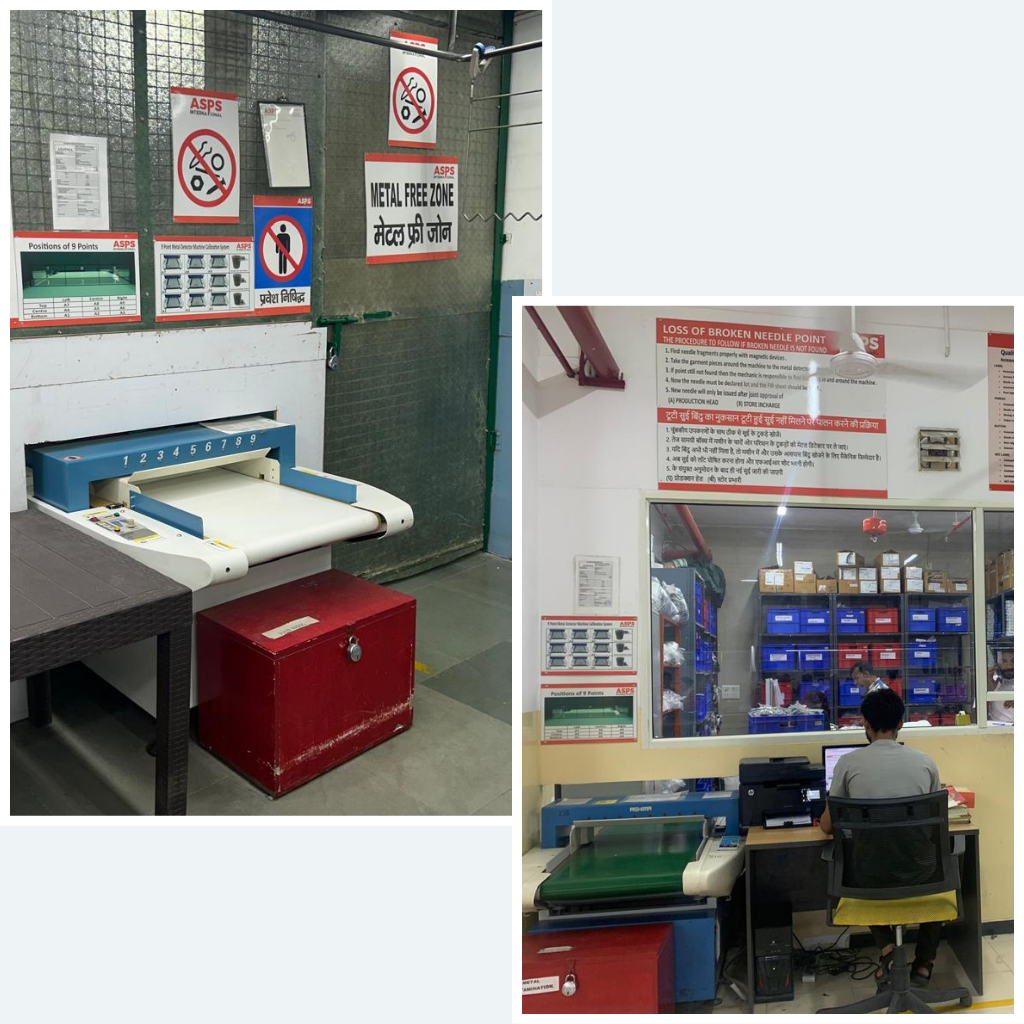

100% needle detection of finished garment

Categorisation of factory in red, yellow & green zone

100% point/broken needle retrivation policy.

Stringent regular check on issuance of any kind of sharp objects.

Packing area are designated meta free zone.

All trims are passed through metal detection before

being stored in the trim store.

We believe that our success should not come at the expense of “better tomorrow”. Through responsible action and innovative thinking, we contribute to the prevention of pollution, energy conservation & sustainable use of raw materials.

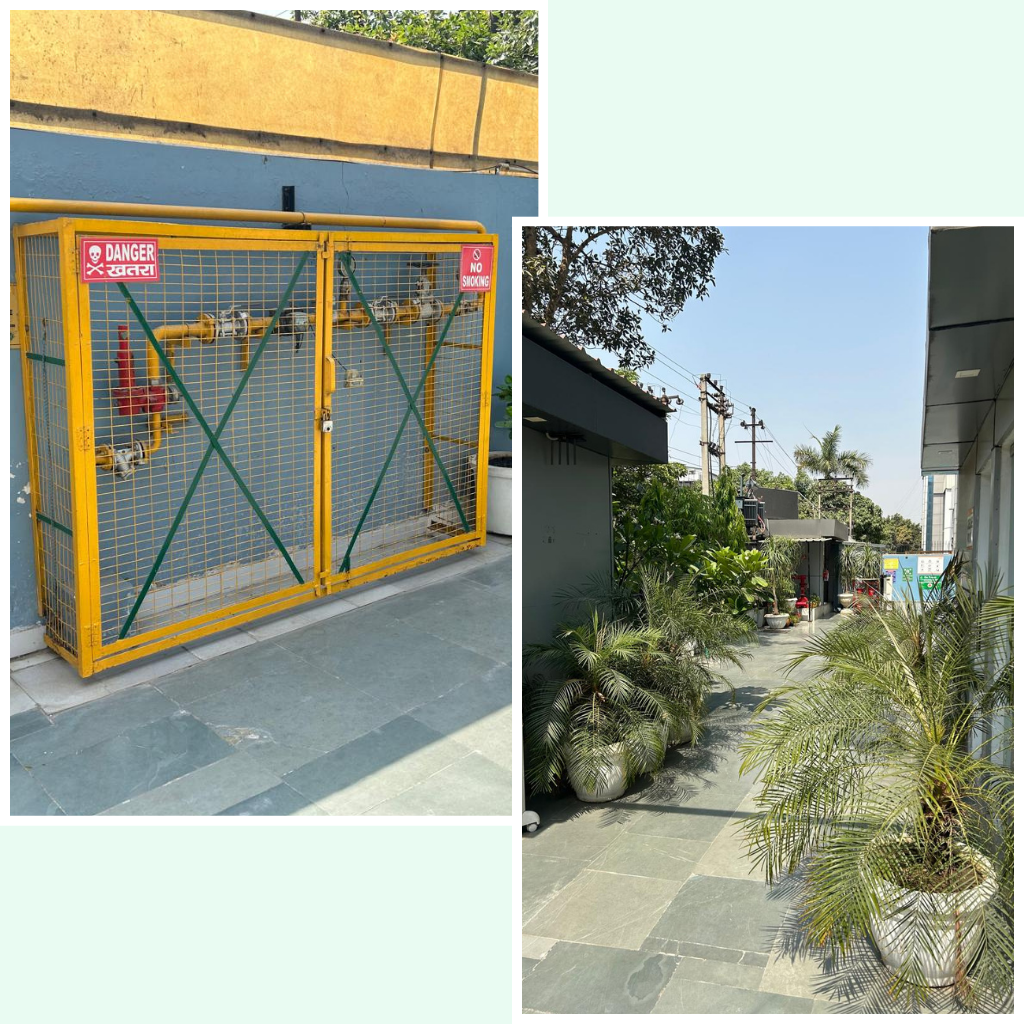

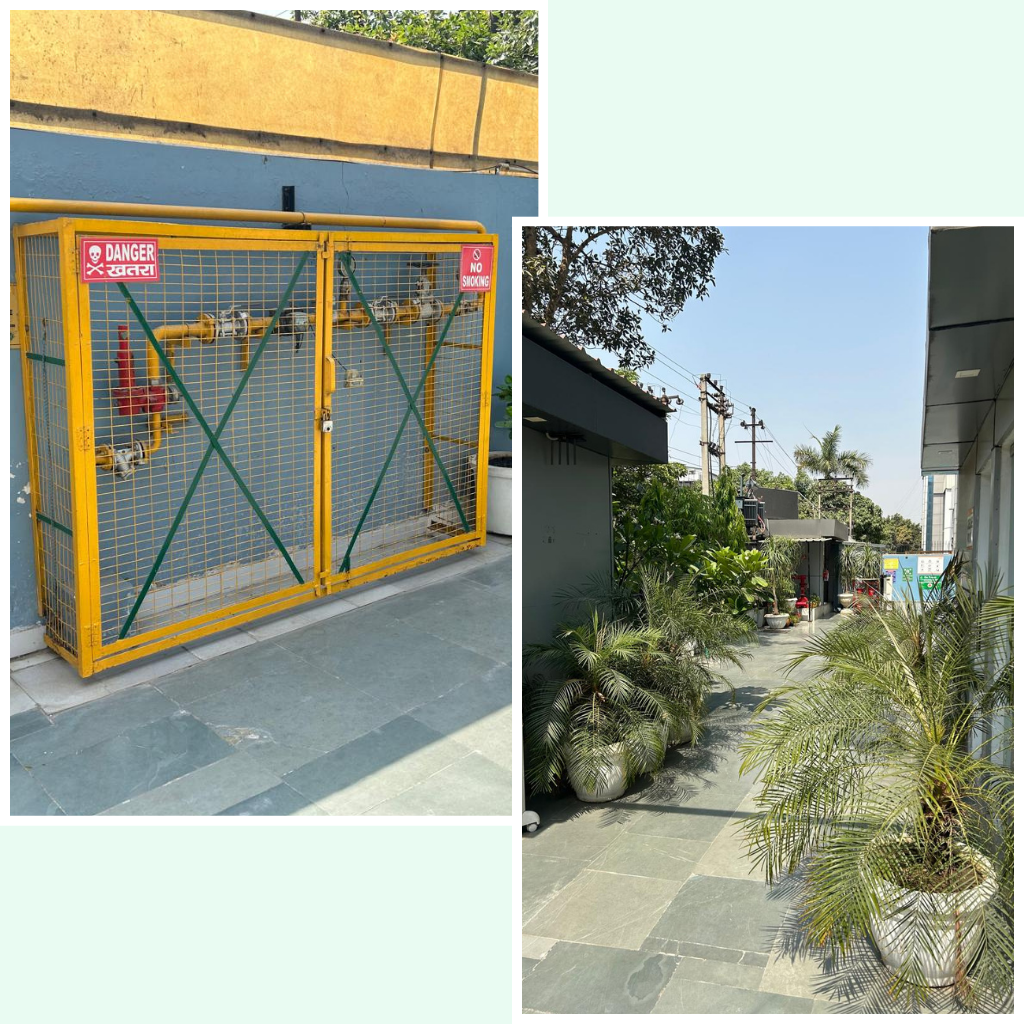

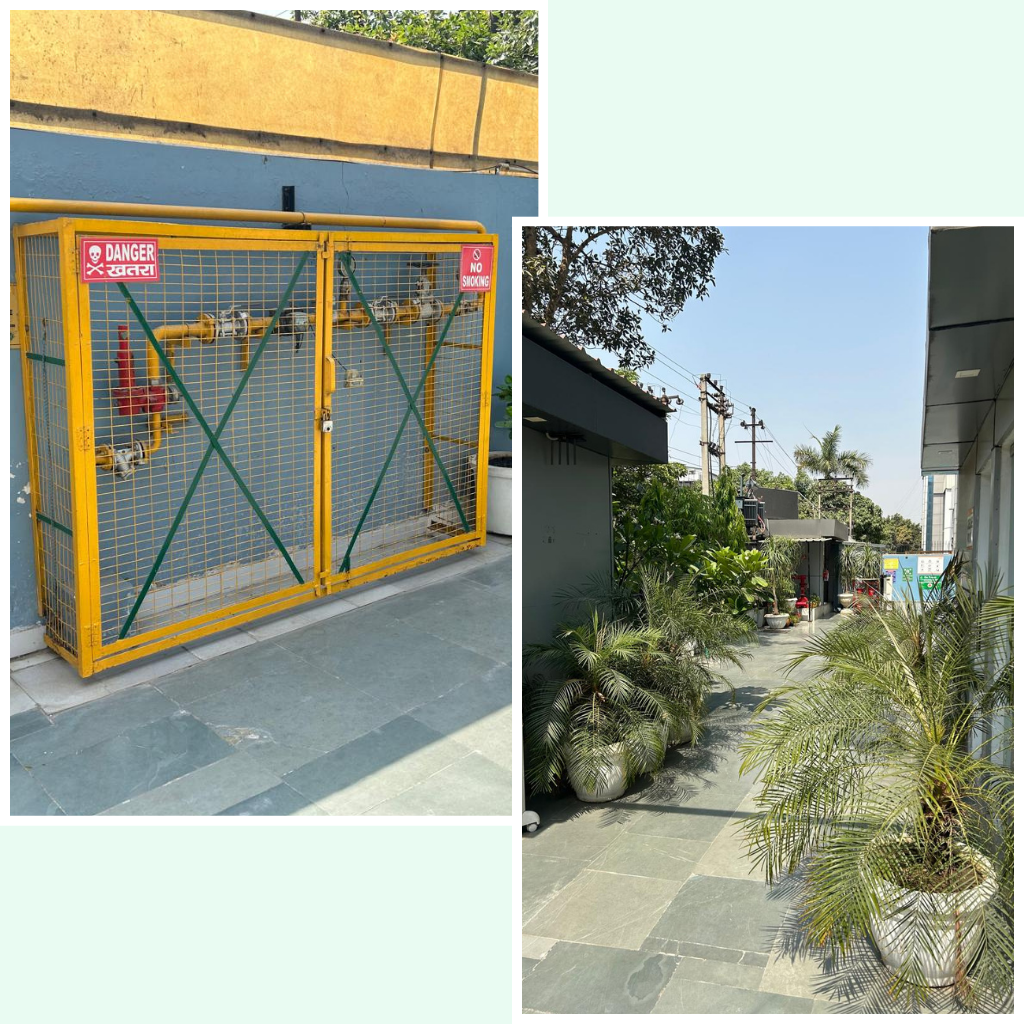

We use liquefied petroleum gas instead of diesel to ignite our boiler. It is a cleaner-burning fuel that emits 14% less CO2 emissions than gasoline automobiles and 10% fewer than diesel cars. It also emits half as much nitrogen oxides as gasoline and a quarter as many as diesel.

Unlike other manufacturing units, we trap the steam from the boiler and reuse the condensate to run the boiler. This helps in saving electricity and also saves on the consumption of LPG to run the boiler.

We practice rain water harvesting.

The entire plant uses LED lights, which are much more efficient in the use of electricity, are cooler, don’t waste energy as heat and thus safer.

As a company we take extra effort to make our surroundings and factory area green.

We have a tie up with “Bharat Oil and Waste Management Ltd”, for proper disposal of sharp metal tools like cutters, scissors, broken tube lights, recyclable paper, fabrics and used oil.

The company is now installing a solar plant. 90% of energy consumption will be derived from the solar plant, thus reducing costs, carbon footprint and promoting sustainability.

ASPS INTERNATIONAL operates as a SEDEX-compliant factory, undergoing regular third-party audits. Our steadfast commitment lies in upholding ethical business standards, aiming not only to meet but surpass local regulations and align with global standards. By doing so, we uphold our clients’ reputations and sourcing principles.

We believe that our success should never come at the expense of the environment. By acting responsibly and thinking innovatively, we strive to prevent pollution, conserve energy, and use raw materials sustainably. We are dedicated to minimizing energy consumption and reducing greenhouse gas emissions, working tirelessly to protect our planet.

We use liquefied petroleum gas instead of diesel for our boiler, reducing CO2 emissions by 14% compared to gasoline and 10% compared to diesel. It also emits 50% less nitrogen oxides than gasoline and 75% less than diesel, making it a cleaner-burning fuel.

Unlike other manufacturers, we capture boiler steam, reusing condensate to reduce electricity and LPG consumption. This conserves energy and boosts efficiency, underscoring our commitment to sustainable practices.

We practice rainwater harvesting and use energy-efficient LED lights throughout the plant. LEDs are cooler, don’t waste energy as heat, and enhance safety, showcasing our commitment to sustainability and efficiency.

We go the extra mile to ensure our surroundings and factory area are green. Through dedicated efforts, we prioritize sustainability and environmental responsibility in every aspect of our operations.

We’ve partnered with “Bharat Oil and Waste Management Ltd” for safe disposal of sharp metal tools, recyclable paper, fabrics, broken tubelights, and used oil, ensuring responsible waste management.

Our packing polybags, at 50 microns and above, are 100% recyclable and meet government standards, ensuring environmental responsibility in our packaging materials.

Our workplace safety measures include clearly marked emergency routes and exits, smoke and fire detectors, and thoughtfully planned layouts to ensure worker safety. In compliance with ISO standards, we prominently display instructions and warning signs in the factory, using the local language for clarity.

To enhance worker safety, we’ve upgraded workplace conditions, mandated the use of safety equipment, and fostered awareness among our workforce. Implementing measures like mandatory metal gloves during fabric cutting and needle guards during sewing has led to a significant reduction in work-related accidents.

ASPS supports workers with welfare committees, ample canteen space, and safe drinking water, fostering a comfortable environment. We staunchly oppose forced labor, child labor, racism, discrimination, and worker exploitation, actively combating such misconducts to ensure a fair and respectful workplace for all.

ASPS empowers women by promoting their advancement to higher positions and increasing their representation in the workforce. We offer financial aid through an interest-free loan fund during emergencies and foster community through entertainment and celebrations, fostering belongingness and professional growth among employees.

Social responsibility has always been at the heart of our company’s philosophy, guiding our daily actions. We view sustainability as a continuous journey, woven into everything we do. This commitment is evident not only in our products but also in how we care for our employees and develop our value chains.

We handle raw materials and resources with care. All our trims are OEKO TEX certified from interlinings to zips. All poly bags used as packaging material are 100% recyclable made of 50 microns and above. Our hanger and poly bags suppliers are GRS certified. We are proud partners of brands and mills that are BCI certified, and have switched to LIVAECO yarns which is made from a natural fiber and is pro planet.

Our manufacturing process adheres to strict environmental standards to minimize our carbon footprint. We also implement water-saving technologies to reduce our overall consumption. By prioritizing sustainable practices, we aim to lead the industry towards a greener future.

We guarantee high SOCIAL & ETHICAL standards and working conditions for which we ourselves take responsibility.

We are a Sedex compliant factory. The goal is to exceed requirement of local legislation and reach global standard thereby supporting brands and their sourcing principle.

ASPS supports its workers by setting up welfare committees, adequate canteen space, safe drinking water, to ensure that workers are comfortable at workplace.

Our workplace safety measures include clearly marked emergency routes and exits and thoughtfully planned layouts. All instructions and working signs are posted in visible places and in local languages as per ISO standards.

For the safety of our workers we have enforced the use of safety equipments like metal gloves while cutting, needle guards during sewing. Such procedures reduce work related accidents significantly.

ASPS is a 100% fire compliant factory and has fire NOC from fire authorities.

125 smoke detectors across the factory.

85 fire extinguishers.

Monthly training of all employees.

Illuminated fire exits.

Automatic fire extinguishing pumps.

Full internal water pipeline in basement.

Sensor driven fire extinguisher at high risk area.

100% needle detection of finished garment

Categorisation of factory in red, yellow & green zone

100% point/broken needle retrivation policy.

Stringent regular check on issuance of any kind of sharp objects.

Packing area are designated meta free zone.

All trims are passed through metal detection before

being stored in the trim store.

We believe that our success should not come at the expense of “better tomorrow”. Through responsible action and innovative thinking, we contribute to the prevention of pollution, energy conservation & sustainable use of raw materials.

We use liquefied petroleum gas instead of diesel to ignite our boiler. It is a cleaner-burning fuel that emits 14% less CO2 emissions than gasoline automobiles and 10% fewer than diesel cars. It also emits half as much nitrogen oxides as gasoline and a quarter as many as diesel.

Unlike other manufacturing units, we trap the steam from the boiler and reuse the condensate to run the boiler. This helps in saving electricity and also saves on the consumption of LPG to run the boiler.

We practice rain water harvesting.

The entire plant uses LED lights, which are much more efficient in the use of electricity, are cooler, don’t waste energy as heat and thus safer.

As a company we take extra effort to make our surroundings and factory area green.

We have a tie up with “Bharat Oil and Waste Management Ltd”, for proper disposal of sharp metal tools like cutters, scissors, broken tube lights, recyclable paper, fabrics and used oil.

The company is now installing a solar plant. 90% of energy consumption will be derived from the solar plant, thus reducing costs, carbon footprint and promoting sustainability.

Social responsibility has always been at the heart of our company’s philosophy, guiding our daily actions. We view sustainability as a continuous journey, woven into everything we do. This commitment is evident not only in our products but also in how we care for our employees and develop our value chains.

We handle raw materials and resources with care. All our trims are OEKO TEX certified from interlinings to zips. All poly bags used as packaging material are 100% recyclable made of 50 microns and above. Our hanger and poly bags suppliers are GRS certified. We are proud partners of brands and mills that are BCI certified, and have switched to LIVAECO yarns which is made from a natural fiber and is pro planet.

Our manufacturing process adheres to strict environmental standards to minimize our carbon footprint. We also implement water-saving technologies to reduce our overall consumption. By prioritizing sustainable practices, we aim to lead the industry towards a greener future.

We guarantee high SOCIAL & ETHICAL standards and working conditions for which we ourselves take responsibility.

We are a Sedex compliant factory. The goal is to exceed requirement of local legislation and reach global standard thereby supporting brands and their sourcing principle.

ASPS supports its workers by setting up welfare committees, adequate canteen space, safe drinking water, to ensure that workers are comfortable at workplace.

Our workplace safety measures include clearly marked emergency routes and exits and thoughtfully planned layouts. All instructions and working signs are posted in visible places and in local languages as per ISO standards.

For the safety of our workers we have enforced the use of safety equipments like metal gloves while cutting, needle guards during sewing. Such procedures reduce work related accidents significantly.

ASPS is a 100% fire compliant factory and has fire NOC from fire authorities.

125 smoke detectors across the factory.

85 fire extinguishers.

Monthly training of all employees.

Illuminated fire exits.

Automatic fire extinguishing pumps.

Full internal water pipeline in basement.

Sensor driven fire extinguisher at high risk area.

100% needle detection of finished garment

Categorisation of factory in red, yellow & green zone

100% point/broken needle retrivation policy.

Stringent regular check on issuance of any kind of sharp objects.

Packing area are designated meta free zone.

All trims are passed through metal detection before

being stored in the trim store.

We believe that our success should not come at the expense of “better tomorrow”. Through responsible action and innovative thinking, we contribute to the prevention of pollution, energy conservation & sustainable use of raw materials.

We use liquefied petroleum gas instead of diesel to ignite our boiler. It is a cleaner-burning fuel that emits 14% less CO2 emissions than gasoline automobiles and 10% fewer than diesel cars. It also emits half as much nitrogen oxides as gasoline and a quarter as many as diesel.

Unlike other manufacturing units, we trap the steam from the boiler and reuse the condensate to run the boiler. This helps in saving electricity and also saves on the consumption of LPG to run the boiler.

We practice rain water harvesting.

The entire plant uses LED lights, which are much more efficient in the use of electricity, are cooler, don’t waste energy as heat and thus safer.

As a company we take extra effort to make our surroundings and factory area green.

We have a tie up with “Bharat Oil and Waste Management Ltd”, for proper disposal of sharp metal tools like cutters, scissors, broken tube lights, recyclable paper, fabrics and used oil.

The company is now installing a solar plant. 90% of energy consumption will be derived from the solar plant, thus reducing costs, carbon footprint and promoting sustainability.

Sign up to get all the latest fashion news, website updates, offers and promos.

Sign up to get all the latest fashion news, website updates, offers and promos.

Sign up to get all the latest fashion news, website updates, offers and promos.